- Tell : 09131114998

- Email : info@uranus-stone.com

Detection of quality marble

- 1400/08/06 ,

- stone industries Uranus

- 0 Comment

Detection of quality marble

Marble is a natural stone that is used in the construction of residential buildings, public buildings, offices and religious buildings. In addition to flooring, marble tiles are also used behind curtains, table tops, facades and as wall coverings. For more durability, it is recommended to use quality marble. In diagnosing quality marble, pay attention to the following:

Step 1

Turn the marble tile over and look behind it. If the back of the tile appears to be covered with mesh or netting, this stone is more brittle than the rest. This mesh is fiberglass resin and is used to strengthen the stone against cracking or breakage. Such marble may not be suitable for various applications, as it may crack and also break very quickly.

Step 2

Examine the work surface under light and hold it at a 45 degree angle. If there are small pieces and stains on the polished surface of the stone, it may indicate holes that are filled with materials.

Some stones, such as Thassos White marble, have holes filled in the lower grades. Higher quality stones have no cavities filled with epoxy or resin. You should avoid buying stones with fillings that do not match the color of the stone or stones that have large amounts of filler. Over time, the filling may disappear and a hole may be created in the stone to prevent damage to the homeowner. The more you have to patch it.

Step 3

Examine the stone for streaks on its surface and then turn the tile over to see if there are any cracks or crevices in the area behind the stone. Some rocks, such as Crema Marfil, are very prone to cracking and may crack if the crack is deep enough.

Small cracks are common in some stones and you will have no problem using them as wall coverings. Also, for stones that are installed in low traffic areas, the presence of these cracks has no effect on its quality and use.

Step 4

Ask for the full name of the marble along with its sort. For example, Super Marble sort has a higher quality than other sorts.

Also, ask about the hardness factor of marble. If the stone has a high hardness coefficient, but seems to have a resin, filler or fiberglass crack, the stone is not of good quality. A stone with a lower hardness coefficient may have these qualities without affecting the overall quality of the stone or its use.

Read more:

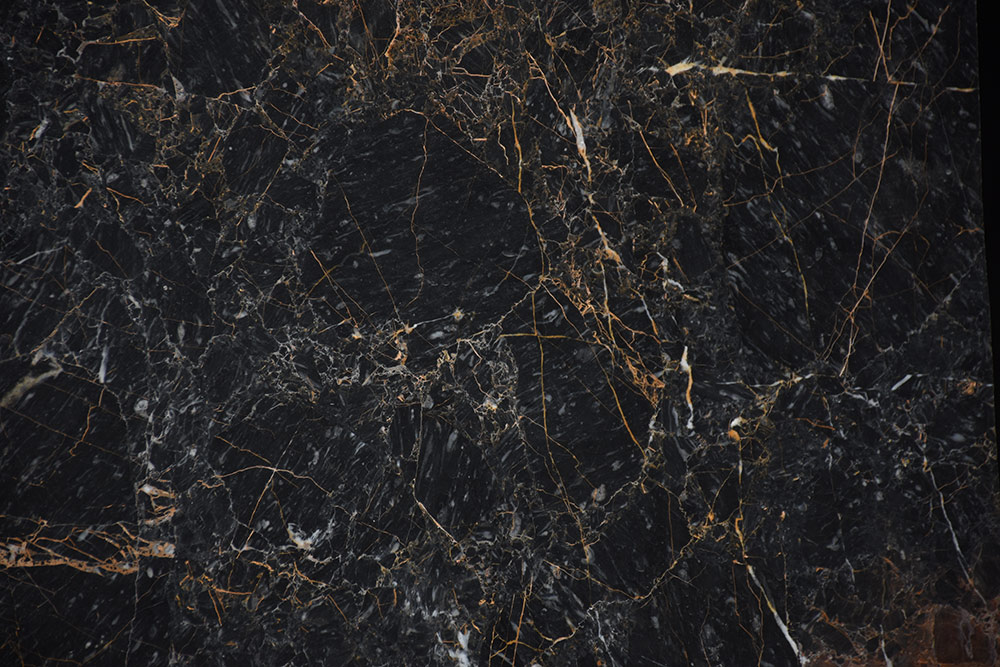

Spider marble

Golden Black marble

Some measures to check the quality of marble

1. Check all the parts in terms of uniformity in color, size and quality according to the specifications.

2. Marble should be polished and have smooth cuts on all four sides.

3. Its thickness should be straight and uniform. Non-uniform thickness leads to uneven flooring and can cause accidents in the house.

4. Marble tiles should be checked for equal sizes. Uneven sizes make it difficult to cut, install and also grout.

5. Along with the front surface, check the back of the marble slab. If the back surface of the lattice is attached to it, it should not be bought because the manufacturers use this lattice material if themarble is brittle or soft.

6. In examining the surface of marble under light with an angle of 45 degrees, if you find surfaces and spots, it indicates low quality. These stains are due to cracks that are filled with material. This type of marble can not be used for busy areas.

7. Marble surface veins should always be checked. When buying, turn the stone upside down and check for cracks or crevices. Sometimes small cracks with streaks are placed on the surface of the marble. Small cracking boards can be used in low traffic areas. If there are large cracks, it is not of good quality.

8. You can also scrape the surface to make sure you choose first-classmarble. If it resists scratches, it is an artificial type and its color changes after installation. Pure marble has little scratch resistance.

9. By dropping 3 to 4 drops of lemon juice (citric acid) on top of its surface, the quality ofmarble can be checked for porosity.

- Marble4

- Marble3

- Marble1

- Marble

- Marble stone

- Granite1

- Granite

- Granite Stone

- 1Chinese

- Chinese stone2

- Chinese stone1

- Isfahan marble

- Isfahan granite

- Travertine1

- Travertine

- Travertine stone

- Isfahan travertine stone

- Stone view1

- Building stone

- Stone facade1

- Stone facade

- Stone cleaning

- Artificial stones

- Natural stones

- Interior decoration

- Cleaning the stone

- Crystal

- Dolomite

- Calcite

- Quartz

- Graphite

- Hematite

- Simonite

- periet

- Manganese carbonate

- Lemonite

- Stone resistance

- Natural stone

- Artificial Stone

- Stone flooring

- Marble of the Emperor

- Dehbid cream marble

- Dehbid marble

- Persian Rose Marble

- Persian Marble

- Persian Rose Stone

- Marshall Black Marble

- Marshall Marble 1

- Black marble

- Marshall Black Stone

- Black Marshall Marble

- Spider black marble

- Spider marble 1

- Black Spider Stone

- Isfahan Chinese stone

- Black marble of Najafabad

- Najafabad marble

- Marble of Najafabad

- Black marble of Najafabad1

- Porcelain stone

- Gallstone

- Bath stone

- Stone toilet

- Aligudarz Chinese stone

- Qorveh Chinese stone

- Qorveh crystal stone

- Sirjan porcelain stone

- Sirjan crystal stone

- Plinth stone

- Duplicate stone

- Gabbro stone

- Gabor

- Black granite1

- Black granite

- Basalt

- exterior view

- Limestone

- Construction industry

- Stone industry

- Stone mine

- Lithology

- Khoy red marble

- crystal

- crystal stone

- Azna crystal stone

- Iranian crystal stones

- Persian Latte marble

- Persian Scots stone

- Persian Scots crystal stone

- Spider Marble

- Lashtar marble

- Pietra Gray Marble

- Zebra crystal stone

- Qorveh Saiman crystal stone

- floor stone

- Delicatus granite

- Granite Fusion

- Icy white granite

- Alaska White Granite

- Ice Flower marble

- Carrara Marble

- Macarana Marble

- Sperlus crystal

- Nehbandan granite

- Mashhad Pearl Granite

- Royal Black marble

- Najafabad black marble

- Abadeh marble