- Tell : 09131114998

- Email : info@uranus-stone.com

Stone recycling is a way to use natural stone

- 1400/12/23 ,

- stone industries Uranus

- 0 Comment

Stone recycling is a way to use natural stone

Stone recycling is a way to use stone waste with low cost and high productivity. Many stone wastes are produced in production plants that apparently have no other function, but the same wastes can be reused with recycling. Nowadays, recycling can greatly reduce costs in many cases. It has become possible in stone production workshops to use rock waste for production.

Benefits of stone recycling

Recycling of building stone is very important to prevent the loss of this natural and valuable material and the optimal use of waste stones produced by various factories. This work is done in modern workshops and in a separate environment from manufacturing factories, which has also received a lot of attention in terms of job creation plan.

In this regard, human resources, specialists and experts in this field are working and it is also possible for women to work in this type of workshops. Stone can be considered a national asset and the reuse of recycled stones can be a way to reduce costs and The return on this capital.

The stone recycling plan has a very good economic justification because the throwing of stones and stone waste in the quarries is minimized and the waste is significantly reduced. Also, their use will increase the profit and create a suitable business.

Read more:

Solution to get rid of dandruff

How recycled stones are formed

Waste rock can occur in factories for a variety of reasons. Stone tops that enter the factory produce waste when cut if it has cracks. The rocks produced from these peaks will usually have less resistance. Inaccuracy during transportation may cause cracks, scratches and fractures at the edges and surface of the stone, or may cause lesions during abrasion.

Which stone is suitable for the body of the parking lot? Also, if the extension of the stone layers is not parallel to the folds, the stone can have more fractures. Explosive mines are another factor that leads to the production of waste. In these mines, due to the explosion on the rocks, joints are created which, when cut, lead to the breaking of plaque and waste. Travertine stone,

Stone recycling methods

Stone recycling can be done in different ways and waste stones can be used to produce different items. Here are some common types of rock recycling:

Antique rock

Antique stone can be produced by putting together broken and broken pieces of other stones. This type of stone can be produced from waste stones and broken travertine stones. These parts are glued together with mortar from resin base and produce a set that has a high beauty and quality and is called decorative or antique stones. These parts have different shapes and this irregularity gives a special beauty to the produced product.

Solution to get rid of dandruff

The most important reasons for using travertine to produce antique stone include:

- high resistance

- Excellent strength and ductility

- Appearance beauty and color variety

- Existence of porosity for gluing parts and penetration of mortar between them

- Leather the upper layers of the stone to produce antique stone

In this method, special plastic brushes are used on the surface of the stone, which makes the surface of the stones leathery. This method can be used for leathering marble, marble, travertine and all kinds of porcelain.

Benefits of Antique Gems

One of the most important advantages of using antique stones that come from the recycling of other stones can be:

- Reasonable price of these stones

- High installation speed

- The lowest throw compared to ordinary natural stones

- Ability to install on round surfaces

- Ability to install after completion of construction work

- Variety in color, design and model and size and type of stone

- River rocks or rubble

The rocks that collide with each other in the river and roll on top of each other have an almost smooth and polished surface and they can be used as facade stones and floor stones of the building. These stones are installed with cement-sand mortar on brick or concrete surfaces, so that the rubble gives a special effect to the facade and has a great impact on the final beauty of the facade.

What is explicit?

To install this type of stone in the facade, suitable molds should be used until the mortar is completely set. Rubble can also be used as slab stones on a special grid in standard dimensions.

Cubic or cubic stone

These stones are cut by a guillotine and usually have uneven surfaces. Reuse and recycling of stones, which are called rock pieces, have different uses such as:

- Urban

- Paving sidewalks

- Roadside tabulation

have.

Stone and interior decoration

These types of stones are used for construction activities by the municipality and other organs, which are the largest consumers of waste stones and stone recycling.

From waste for stone recycling as:

- Artificial Stone

- Stone powder

- Types of cement

- Special asphalts

- Ceramic floor coverings

Can also be used.

Depending on the type of stone, various stone recycling products can be obtained. Stronger stones are usually used for facades and floor stones, and softer stones are usually in the form of powder, antique stone, etc. Other applications of waste stone recycling include porcelain carcasses for the entrance floor of buildings, sidewalks, parking lots, etc. Stone blocks that can not be cut due to their small size and can be used as a building stone can also be made using special cutting and turning machines to make:

- flower pot

- Cup

- stone dishes

And ...

Be used.

What is rock analysis?

The economic justification of this plan is that the throwing of quarry stones is minimized and ultimately does not exist as waste in factories, and in addition to appropriate profits and returns, it creates jobs for job seekers and educated people in accordance with this job and profession. Granite,

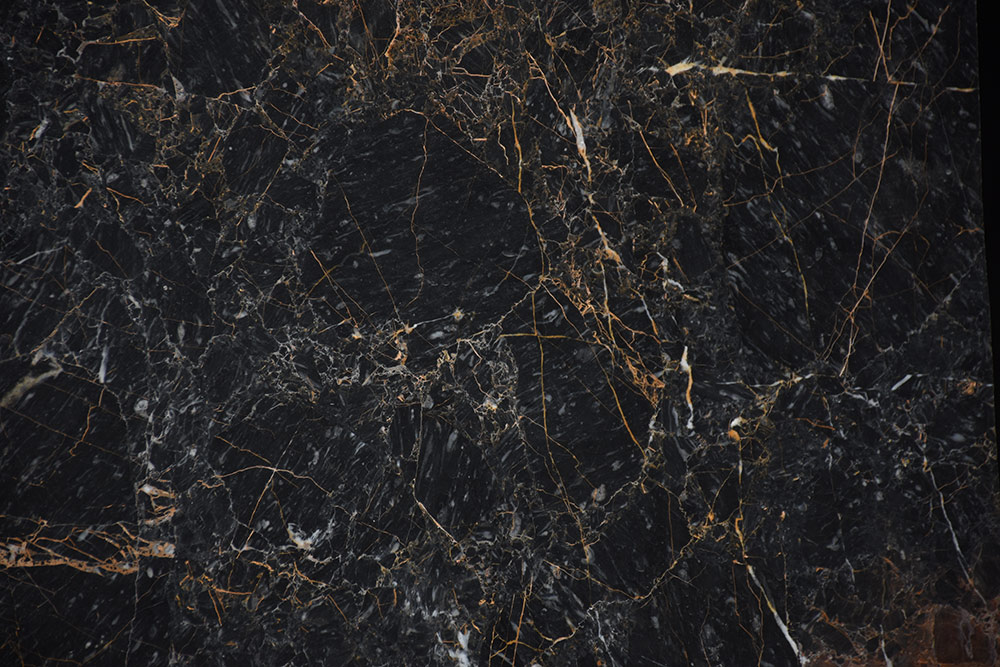

Some products of Uranus stone industry : Spider marble stone ، Marshall Marble ، Dehbid cream marble ، Jaguar marble ، Marble Stone

Contact Uranus for more information.